As someone who has been playing around with heat transfers for more than 40 years, I'm anxious to spread the word about what can be done with them ... and with very little investment! Did the "kitchen table" thing catch your attention?

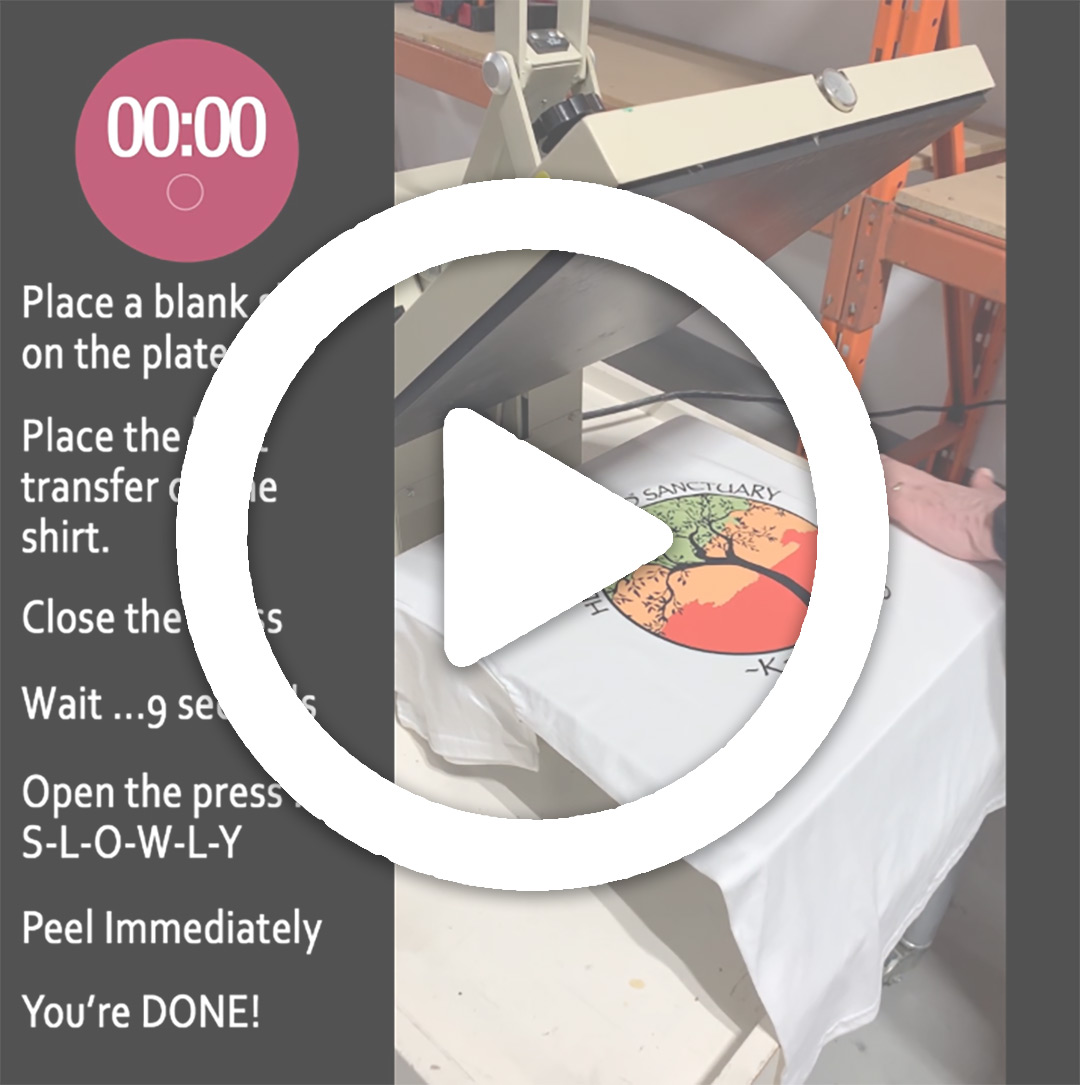

Well, when you watch the video, obviously we didn't do it on an actual kitchen table! But we could have ... just as easily! The vintage heat press used in the video just plugs right into any ordinary 110v/1500amp socket.

That's it! There's no air compressor, ventilation, or special hydro needed. In 30 seconds you've got a 4-colour finished product that's every bit as good as any screen shop can do*. No ink! No mess! No cleanup!

The point is that, using heat transfers and a simple heat press, you actually could do screen printing jobs right on your kitchen table, or in your basement. Now, I'm sure your family would no doubt prefer that you set something like this up in the basement or garage ... not the kitchen. But you get what I'm saying!

So ... say that you're a young entrepreneur with all kinds of great ideas for printed tees and sweaters. You think you could sell lots online, but you have to get them printed! Printers will only take orders with some decent sized minimums ... otherwise you're paying more that you can sell for! Oops ... that won't work! DTG printers costs thousands and the cost of the print can be very high? Could printing as needed with a heat press work for you?

Or maybe you're an embroidery shop, and you're already in contact with hundreds of potential screen print customers every month. Every week you get asked about small to medium screen print jobs ... a couple of dozen tees ... a few hoodies ... even as low as 12! You can't get a screen printer to do it. Setting up your own shop costs (tens of) thousands of dollars. So you watch them walk away ... nothing you can do! Or is there?

What if you're a specialty wholesale shop? Dealing with a niche market ... say selling winemaking supplies to winemaking shops all across the country. Could you add a line of "wine lovers" t-shirts that you could print in house as needed. If your customers could buy them as needed along with their regular supplies could that be an extra profit centre for you, and them?

What about special events? Did you know you can take a heat press and set it up at events, tournaments, concerts ... and sell shirts that pertain to that event. Just print them as needed. The shirts you don't print are good for the next time.

Question: If you can print 100 t-shirts per hour, and you make $5.00 profit on each t-shirt ... does that mean you're making $500/hr? Answer: Yes!

Printing with heat transfers starts with the heat press machine. Check out my blog on what kind of machines you should and shouldn't be considering. We don't sell machines, so I'll give you my un-varnished opinions and my reasons why. If any of you experienced heat pressers out there have found your favorite press email me about it. We can share the info through the blog.

About the heat press. We picked up this rare, vintage (Canadian Made) beauty for $300 a few years ago. It had been in storage for many years, but had been well cared for, virtually unused and still is pretty well in showroom condition. This is about as basic as it gets for a heat press, and as you can see this one does a great job printing t-shirts. We use it for sampling the quality of our custom transfers before we ship. Your chances of finding something like this at this price are low, but they are out there! Hey, you may even have one yourself! Let's get it out of storage.