One of the major challenges when screen printing white ink is the problem of bleed when printing on dark garments. Whether its direct screen printing or using screen printed heat transfers keeping the result pure white can be elusive. And printing on red is usually the worst!

For direct screen printing the usual solution is to hit the garment with your white print, flash it, and then hit it again. That's a bunch of extra work and you end up with a really thick layer of ink. If you are printing lightweight garments, such as t-shirts, it can be a bit nasty!

New DTF transfers solve the bleed problem, but if you are using a large print, say 11x15, and it only has white, you're going to pay quite a bit for a DTF sheet that size. And you won't get the benefit of CVP pricing! You'll pay the same for more.

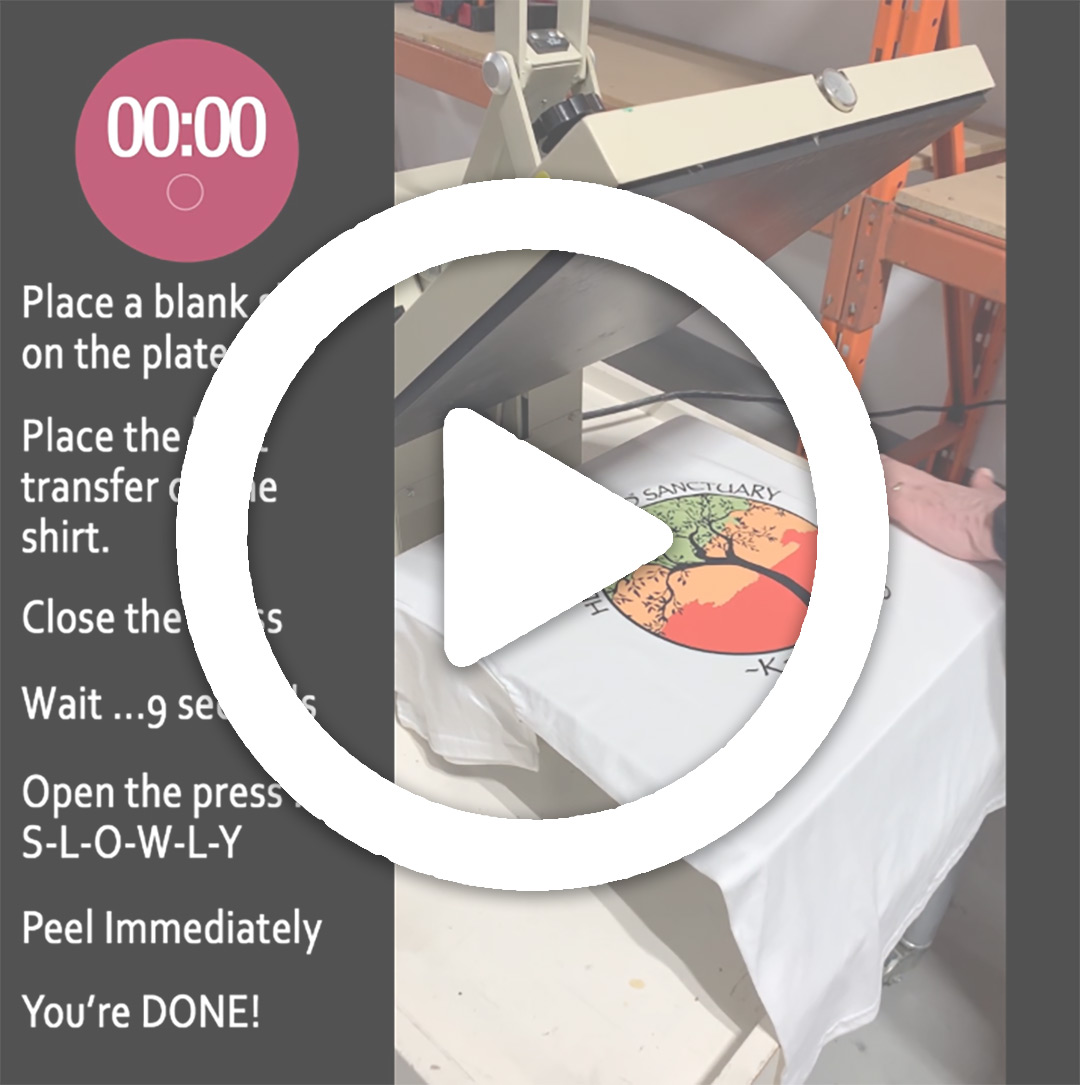

Using our DyeBlocker™ transfers on pretty well any fabric is a cost-effective alternative to DTF when doing runs of 12 or more. The result is a pure white print, even on red garments, and it does not have a thickness or stiffness that can be undesirable. Plus its a lot easier than using vinyl, which can also produce an undesirable result in terms of the hand of the print.

But its not just for white! All ink colours have incredible opacity and durability, making DyeBlocker™ transfers ideal for team apparel. You can have any number of Pantone® matched colours and with low-temp pressing you can go on pretty well every fabric.

If you haven't tried our DyeBlocker™ transfers to solve your bleed issues why not request a sample pack and give them a try. You'll be surprised at the result.